Running Tracks

We are proud to be one of the largest running-track installers in Kentucky. Servicing thousands of running tracks, we have the knowledge and resume for building championship caliber tracks. We offer the installation, refurbishment, and repair of latex and polyurethane based tracks with EPDM, SBR, or natural rubber granules or strands.

We also offer free consultation and free construction estimates for our track surfaces. Because track surfaces differ greatly, it is important to speak to the experts before choosing a surface. Track durability, thickness, surface-life, and maintenance cost are all important factors one must understand before choosing the surface that is right for you. While some surfaces might be less expensive to install, they may not last as long or they may come with high maintenance costs. With over forty-plus years experience, we have the knowledge to help you build the best running track suitable for your facility and your athletes' needs.

Polyresin Technology

Of the many track types, polyresin tracks are some of the most affordable, vibrant, and low-cost/high-value track surfaces available. The polyresin track is low on long-term maintenance costs because it can be refurbished multiple times. Most non-polyresin tracks will need to be completely removed and reinstalled which causes long-term costs to be a bit higher.

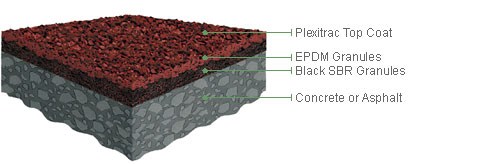

Tennis Technology, Inc., is proud to be a certified installer of California Products' polyresin track surfaces. These surfaces are IAAF certifiable, affordable, and carry warranties if installed by Tennis Technology, Inc. These award winning tracks are LEED compliant, use 45-64% recycled materials, and do not require the use of toxic solvents at the project site. The reliability, durability, and all-around high performance of Plexitrac is why we recommend these surfaces to our clients. Call or email for surface specifications.

Plexitrac Accelerator

Plexitrac Lightning

Plexitrac Surfacer

Track Top 2000

Latex Running Track Surface

One of the most economical and durable track surfaces around is the Track Top 2000. This surface is made up of a mixture of rubber granules ranging in size from 1 to 6 millimeters, bound together with a Styrene Butadiene Latex binder. The rubber granules and binder are applied in multiple applications until the track surface reaches the specified thickness as desired by the owner. The surface thickness can range from 3/8" to 1/2".

The installation of the Track Top 2000 begins with a latex prime coat being applied to the new or old asphalt surface at a rate of .05 gallons (mixed 1 part water to 1 part latex binder) per square yard. Next, a layer of S.B.R. rubber granules (3-to-6 millimeters in size) are spread evenly, either mechanically or manually, at a rate of approximately 2 pounds per square yard. The rubber is sprayed with the latex binder at a rate of .1 gallons per square yard. The amount of binder applied is sufficient to thoroughly saturate all the rubber granules. Once the first layer is cured, a second layer of rubber granules (3-to-6 millimeters in size) will be installed in the same manner as the first, but at a rate of 2.5 pounds per square yard. This layer of rubber will then be saturated with the latex binder at a rate of approximately .2 gallons per square yard. This process is followed until the desired thickness is achieved. The third layer uses rubber granules of 2-to-4 millimeters in size and is spread at a rate of 3 pounds per square yard and is saturated with the latex binder at a rate of .2 gallons per square yard. The final layer is made up of rubber granules ranging from 1-3 millimeters in size. This layer is sprayed with the latex binder mixed with pigment at a rate of 1 part pigment to 11 parts latex binder. Once the final layer has cured, a final spray coating of pigmented Track Top 2000 latex binder mixed with Track Top dispersed pigment is installed at a rate of .05 gallons per square yard.

The layers installed are dependent upon the desired level of thickness. The above specification references the Track Top 2000 3/8" track surface. We have found The Track Top 2000 to be a superior product given the price and durability. The Track Top 2000 surface has been installed at numerous high-schools, colleges, and universities throughout Kentucky, Southern-Indiana, and Southern-Ohio. Call today for a list of local tracks with the Track Top 2000 brand.